Liquid Kalium Zinc PVC Stabilizer

Liquid Kalium Zinc PVC Stabilizer is an innovative accelerator that enhances the thermal decomposition of azodicarbonyl (A.C) chemical, effectively reducing the foaming decomposition temperature of A.C and accelerating the foaming speed, resulting in higher foaming ratio and excellent heat stability.

One of its primary applications is in the processing of PVC floor leather, where it plays a crucial role in achieving desirable foaming properties, ensuring the quality and durability of the leather. Additionally, it finds extensive use in the manufacturing of shoe soles, contributing to the overall comfort and performance of footwear through enhanced foaming ratio and heat stability.

|

Item |

Metal Content |

Characteristic |

Application |

|

YA-230 |

9.5-10 |

High Production Efficiency, High Foaming Rate, Odorless |

PVC Yoga mats, car floor mats, foam wallpapers, decorative panels, etc. |

|

YA-231 |

8.5-9.5 |

High Cost-effectiveness |

Furthermore, the Liquid Kalium Zinc PVC Stabilizer proves highly beneficial in the production of foam wallpapers, providing enhanced foaming characteristics that enhance the appearance and functionality of wallpapers. Its improved heat stability ensures the longevity of wallpapers, making them suitable for various interior design applications. The improved foaming ratio ensures consistency and aesthetics in the finished decorative products, meeting the demands of the interior design industry.

Moreover, this stabilizer finds wide application in decorative materials, adding value to the production of foamed decorative elements such as panels and moldings.

In conclusion, the Liquid Kalium Zinc PVC Stabilizer is an indispensable tool in the PVC processing industry. By effectively accelerating the foaming decomposition of azo-dicarbonyl, it enables manufacturers to achieve higher foaming ratio and heat stability, thereby enhancing the quality, durability, and performance of various PVC foam products. Its extensive applications in PVC floor leather, shoe soles, foam wallpapers, and decorative materials demonstrate its adaptability and potential to drive various industries towards sustainability and superior performance, reflecting the innovation and progress in the modern PVC processing industry.

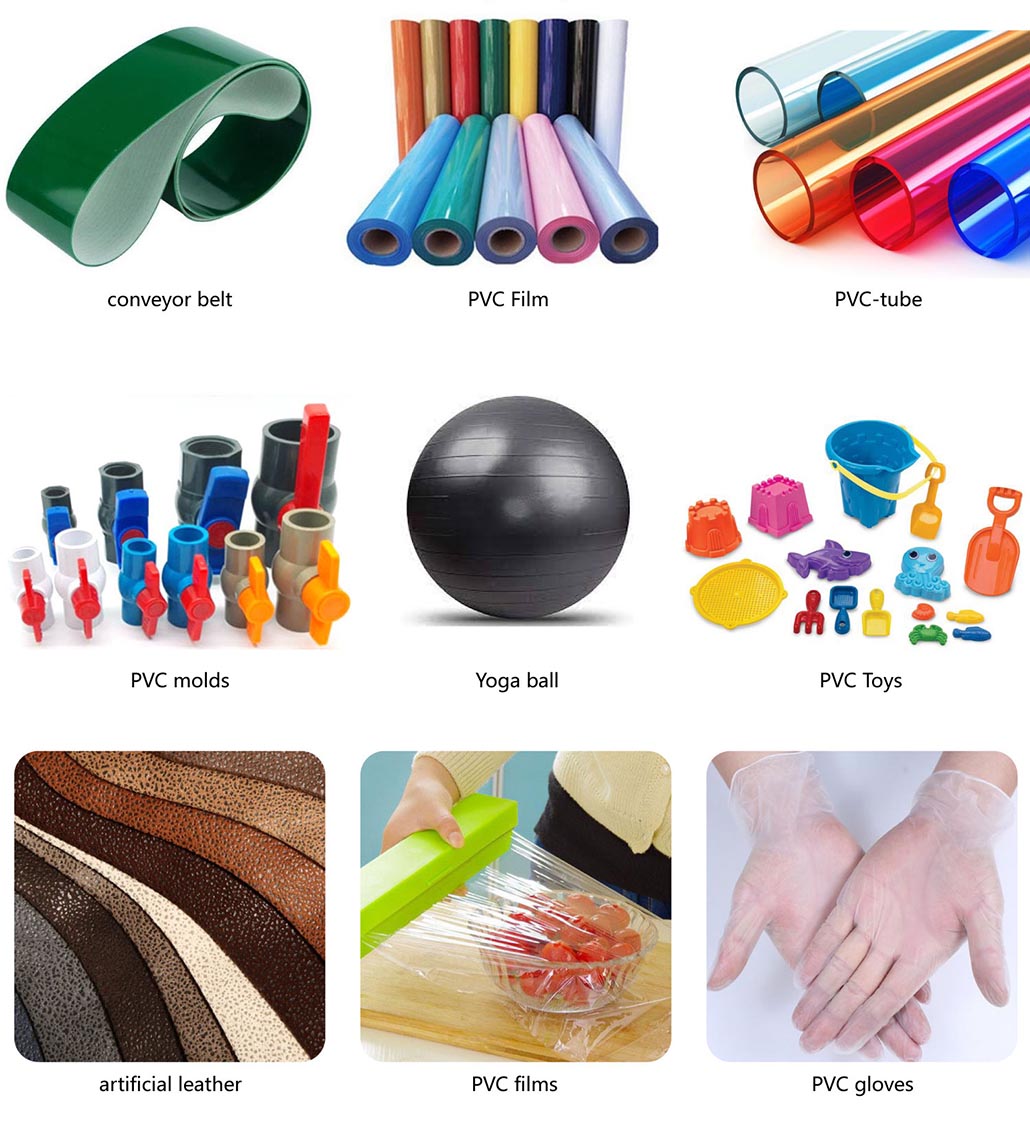

Scope of Application