PVC conveyor belt is made of Polyvinylchloride, which is composed of polyester fiber cloth and PVC glue. Its operating temperature is generally -10°to +80°, and its joint mode is generally an international toothed joint, with good lateral stability and suitable for transmission in various complex environments.

PVC Conveyor Belt Classification

According to the classification of industry application, PVC conveyor belt products can be divided into: printing industry conveyor belt, food industry conveyor belt, wood industry conveyor belt, food processing industry conveyor belt, stone industry conveyor belt, etc.

According to the performance classification can be divided into: light climbing conveyor belt, baffle lifting conveyor belt, vertical elevator belt, edge sealing conveyor belt, trough conveyor belt, knife conveyor belt, etc.

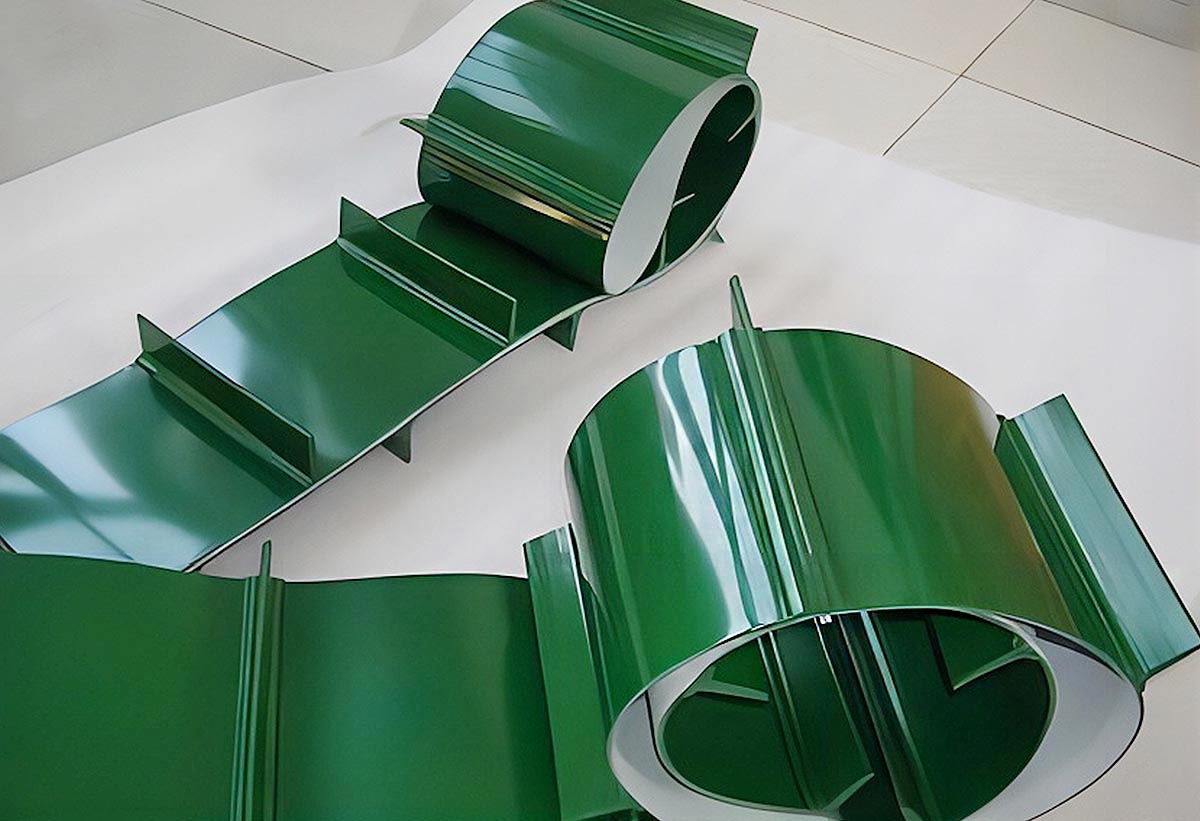

PVC conveyor belt

According to the product thickness and color development can be divided into: different colors (red, yellow, green, blue, gray, white, black, dark blue green, transparent), thickness of the product, the thickness from 0.8MM to 11.5MM can be produced.

The Application of PVC conveyor belt

PVC conveyor belt is widely used, mainly used in food, tobacco, logistics, packaging and other industries. It is suitable for underground transportation of coal mines, and can also be used for material transportation in metallurgical and chemical industries.

How to improve the performance of PVC conveyor belts?

The material of PVC conveyor belt is actually ethylene based polymer. There are several ways to extend the service life of PVC conveyor belts:

1. A dense belt core woven from warp and weft filament and covered cotton spinning;

2. Immersed with specially formulated PVC material, it achieves extremely high bonding strength between the core and the cover adhesive;

3. Specially formulated cover glue, making the tape resistant to impact, tear, and wear resistance.

Post time: Apr-01-2024