PVC (Polyvinyl Chloride) pipe fittings are ubiquitous in modern infrastructure, spanning plumbing, drainage, water supply, and industrial fluid transport. Their popularity stems from inherent advantages: chemical resistance, cost-effectiveness, and structural rigidity. However, PVC’s molecular structure—characterized by repeating vinyl chloride units—renders it susceptible to degradation under thermal, oxidative, and UV stress. This is where PVC stabilizers play a critical role: they mitigate degradation, ensuring pipe fittings retain mechanical integrity and performance over their service life. Below is a detailed analysis of their applications, mechanisms, and selection criteria in PVC pipe systems.

1. Why Do PVC Pipe Fittings Require Stabilizers

PVC undergoes irreversible degradation when exposed to elevated temperatures (typical in extrusion or injection molding processes) or prolonged environmental stress (e.g., sunlight, moisture, or chemical exposure). The primary degradation pathway is dehydrochlorination: heat or UV energy breaks the weak C-Cl bonds, releasing hydrochloric acid (HCl) and initiating a chain reaction that leads to polymer chain scission. This manifests as:

• Discoloration (yellowing or browning)

• Loss of impact strength and flexibility

• Cracking or embrittlement, compromising leak resistance

• Contamination of transported fluids (critical in potable water systems)

Stabilizers interrupt this process, making them indispensable in PVC pipe production.

2. Mechanisms of PVC Stabilizers in Pipe Fittings

Stabilizers function through multiple synergistic mechanisms to protect PVC:

• HCl Scavenging: Neutralize released hydrochloric acid, preventing it from catalyzing further degradation.

• Free Radical Inhibition: Terminate chain reactions initiated by heat or UV-generated free radicals.

• Metal Ion Sequestration: Bind trace metal impurities (e.g., iron, copper) that accelerate degradation.

• UV Shielding: Reflect or absorb UV radiation, critical for outdoor pipe applications (e.g., above-ground drainage).

• Lubrication Aid: Some stabilizers (e.g., UV stabilizers), calcium stearate reduce friction during processing, preventing overheating.

3. Types of Stabilizers Used in PVC Pipe Fittings

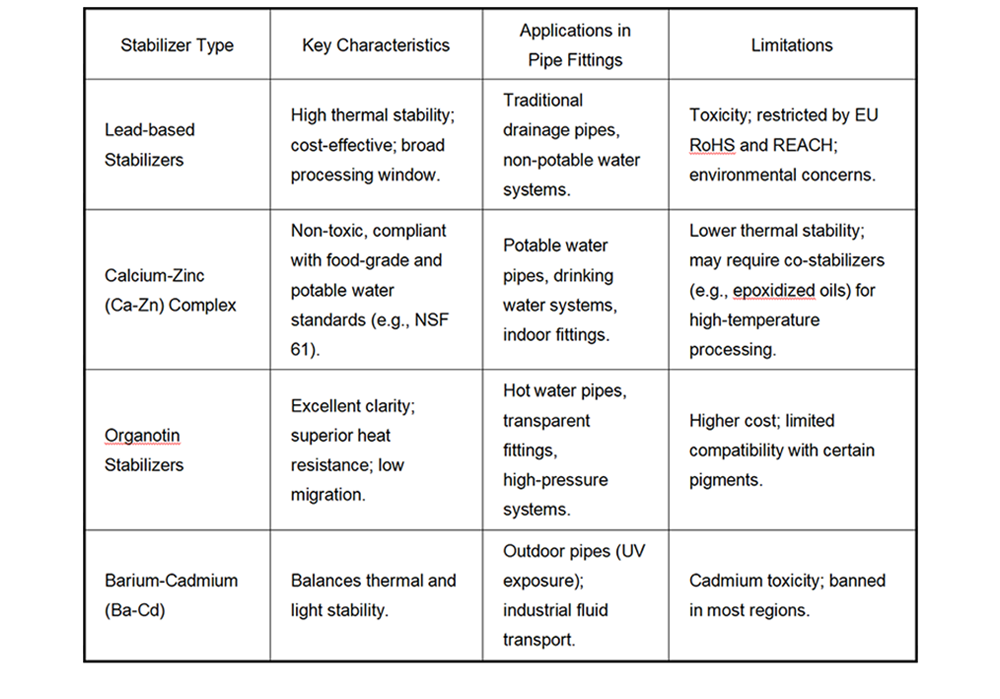

The choice of stabilizer depends on processing conditions, end-use requirements, and regulatory compliance. Common types include:

4. Critical Selection Criteria for Pipe Fittings

When specifying stabilizers for PVC pipe fittings, manufacturers must consider:

• Processing Parameters: Extrusion/molding temperatures (160–200°C for pipes) and dwell times dictate the required thermal stability. High-temperature processes (e.g., hot water pipes) demand stabilizers with robust heat resistance (e.g., organotin).

• End-Use Environment: Pipes for potable water require NSF/ANSI 61 or WRAS certification, favoring Ca-Zn or organotin stabilizers. Outdoor pipes need UV stabilizers e.g., hindered amine light stabilizers ( HALS).

• Regulatory Compliance: Global restrictions on heavy metals (Pb, Cd) push the industry toward eco-friendly alternatives (Ca-Zn, organic-based stabilizers).

• Cost vs. Performance: While lead-based stabilizers are cheaper, long-term costs (e.g., regulatory fines, recycling challenges) favor sustainable options.

5. Emerging Trends in Stabilizer Technology

As environmental regulations tighten and sustainability gains priority, the PVC pipe industry is shifting toward:

• High-Efficiency Ca-Zn Systems: Enhanced with co-stabilizers (e.g., polyols, zeolites) to match the thermal performance of lead-based alternatives.

• Multifunctional Stabilizers: Combining thermal stability, UV resistance, and lubrication in a single additive to simplify formulations.

• Bio-Based Stabilizers: Derived from renewable resources (e.g., plant-based esters), aligning with circular economy goals.

PVC stabilizers are foundational to the performance and longevity of PVC pipe fittings, enabling their safe and reliable use across critical infrastructure. From preventing degradation during manufacturing to ensuring decades of service in harsh environments, their role is irreplaceable. As the industry evolves, the focus on low-toxicity, high-performance stabilizers—particularly calcium-zinc complexes—will drive innovation, balancing functionality with environmental responsibility. For engineers and manufacturers, selecting the right stabilizer is not merely a technical choice but a commitment to durability, safety, and regulatory compliance.

Post time: Sep-02-2025