As a cutting-edge additive for polyvinyl chloride (PVC) processing, Paste Calcium Zinc (Ca-Zn) PVC Stabilizer has emerged as a preferred alternative to traditional heavy metal-based stabilizers (e.g., lead, cadmium). Its unique combination of safety, performance, and environmental compliance addresses critical needs across high-demand PVC product sectors. Below is a detailed breakdown of its core advantages, expanded application scope, and how it resolves long-standing pain points in PVC manufacturing.

1. Core Advantages: Safety, Performance, and Compliance

Paste Ca-Zn PVC Stabilizer stands out for its multi-dimensional performance, making it suitable for both general and high-specification PVC processing.

1.1 Non-Toxic & Eco-Friendly Compliance

Free from harmful heavy metals (lead, cadmium, mercury, etc.), it fully meets global environmental and safety regulations, including the EU’s REACH Regulation, RoHS Directive, and U.S. CPSIA (Consumer Product Safety Improvement Act). This eliminates health risks for production workers and end-users, while avoiding regulatory penalties for manufacturers exporting to international markets.

1.2 Exceptional Transparency & Aesthetic Quality

Unlike some stabilizers that cause PVC to yellow or cloud, Paste Ca-Zn PVC Stabilizer maintains the material’s natural clarity. It preserves high light transmittance even in thin-walled or colored PVC products, a key requirement for applications where visual appeal (e.g., transparent toys, medical tubing) or product functionality (e.g., clear hoses for fluid visualization) is critical.

1.3 Superior Dynamic Stability & Aging Resistance

PVC is prone to thermal degradation during processing (e.g., extrusion, calendering) and oxidative aging during long-term use. This stabilizer forms a protective film on PVC molecular chains, effectively resisting heat-induced decomposition (even at 160–180°C processing temperatures) and slowing down UV/oxidation-related brittleness. Field tests show products formulated with it have a 30–50% longer service life compared to those using conventional stabilizers.

1.4 Excellent Processability & Low Odor

With good compatibility with PVC resins and plasticizers, Paste Ca-Zn PVC Stabilizer ensures uniform dispersion during mixing—reducing production issues like material agglomeration or uneven melting. It also minimizes volatile organic compounds (VOCs) release, resulting in near-odorless end products. This is a game-changer for enclosed-space applications (e.g., refrigerator cleaners) and sensitive sectors (e.g., medical devices).

2. Expanded Application Scope

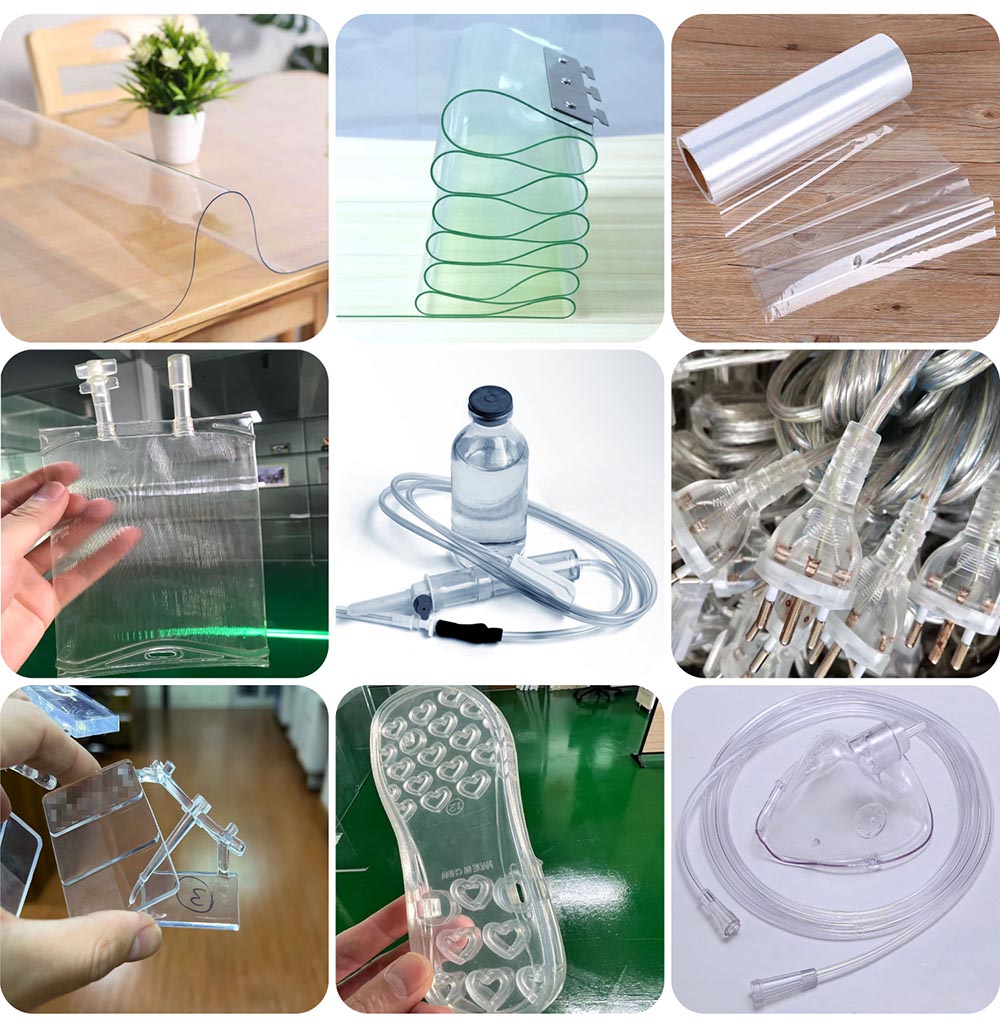

Its versatility makes Paste Ca-Zn PVC Stabilizer ideal for high-transparency, safety-critical, and odor-sensitive PVC products, covering both consumer and industrial sectors:

2.1 High-Transparency PVC Soft & Semi-Rigid Products

• Household & Daily Use: Transparent refrigerator cleaners (resistant to cold temperatures and food contact), clear vinyl gloves (medical or food-grade, non-toxic), and flexible PVC toys (compliant with EN 71 and ASTM F963 safety standards for children).

• Industrial & Utility: Transparent PVC hoses (for water, air, or chemical transfer, where visibility of fluids prevents blockages) and semi-rigid PVC sheets (used in display cases or packaging for electronics).

2.2 Medical-Grade PVC Products (High-Standard, Odor-Free)

Medical PVC requires strict adherence to biocompatibility and sterility. This stabilizer meets ISO 10993 (biological evaluation of medical devices) and USP Class VI standards, making it suitable for:

• Respiratory aids: Oxygen masks and nebulizer tubes (low odor ensures patient comfort during long-term use).

• Fluid management: Intravenous (IV) drip tubes, blood bags (resistant to chemical reactions with blood or medications), and catheters.

• Injection devices: Syringe barrels and medical injection components (non-toxic, ensuring no leaching of harmful substances into bodily fluids).

2.3 Food-Contact PVC Products

Beyond medical use, it is also approved for food-contact applications (e.g., transparent PVC films for food packaging, conveyor belts in food processing plants), as it complies with FDA 21 CFR Part 177.1520 (PVC resins for food contact).

3. Solving Key Pain Points in PVC Production

PVC manufacturers often face challenges related to safety, performance, and compliance—issues that Paste Ca-Zn PVC Stabilizer directly resolves:

3.1 Eliminating Heavy Metal Contamination Risks

Traditional lead-based stabilizers pose risks of worker exposure (via dust or fumes) and end-product contamination (e.g., lead leaching from toys or food packaging). This stabilizer’s heavy metal-free formula eliminates these hazards, avoiding product recalls and protecting brand reputation.

3.2 Overcoming Transparency Loss in Processing

Many stabilizers react with PVC’s plasticizers or resins, causing discoloration or cloudiness. Paste Ca-Zn PVC Stabilizer’s low reactivity preserves clarity, reducing scrap rates for high-transparency products (e.g., 10–15% fewer defective units in toy or medical tubing production).

3.3 Preventing Thermal Degradation During High-Temperature Processing

PVC decomposes at high temperatures, releasing hydrochloric acid (HCl) and causing material discoloration or brittleness. This stabilizer’s strong heat resistance maintains PVC stability during extrusion or molding, ensuring consistent product quality and reducing downtime from equipment corrosion (caused by HCl).

3.4 Meeting Odor & Biocompatibility Requirements for Sensitive Sectors

Medical and household PVC products often fail certification due to residual odors or toxic leachables. This stabilizer’s low VOC emission and non-toxic composition ensure compliance with medical biocompatibility tests and household odor standards, accelerating time-to-market for new products.

Paste Calcium Zinc PVC Stabilizer bridges the gap between safety, performance, and compliance for PVC manufacturers. Its non-toxic, eco-friendly profile meets global regulations, while its transparency, stability, and processability enhance product quality across consumer, industrial, and medical sectors. By solving core challenges like heavy metal contamination, transparency loss, and thermal degradation, it has become an indispensable additive for high-value PVC applications—especially those requiring strict safety or aesthetic standards.

Post time: Aug-29-2025