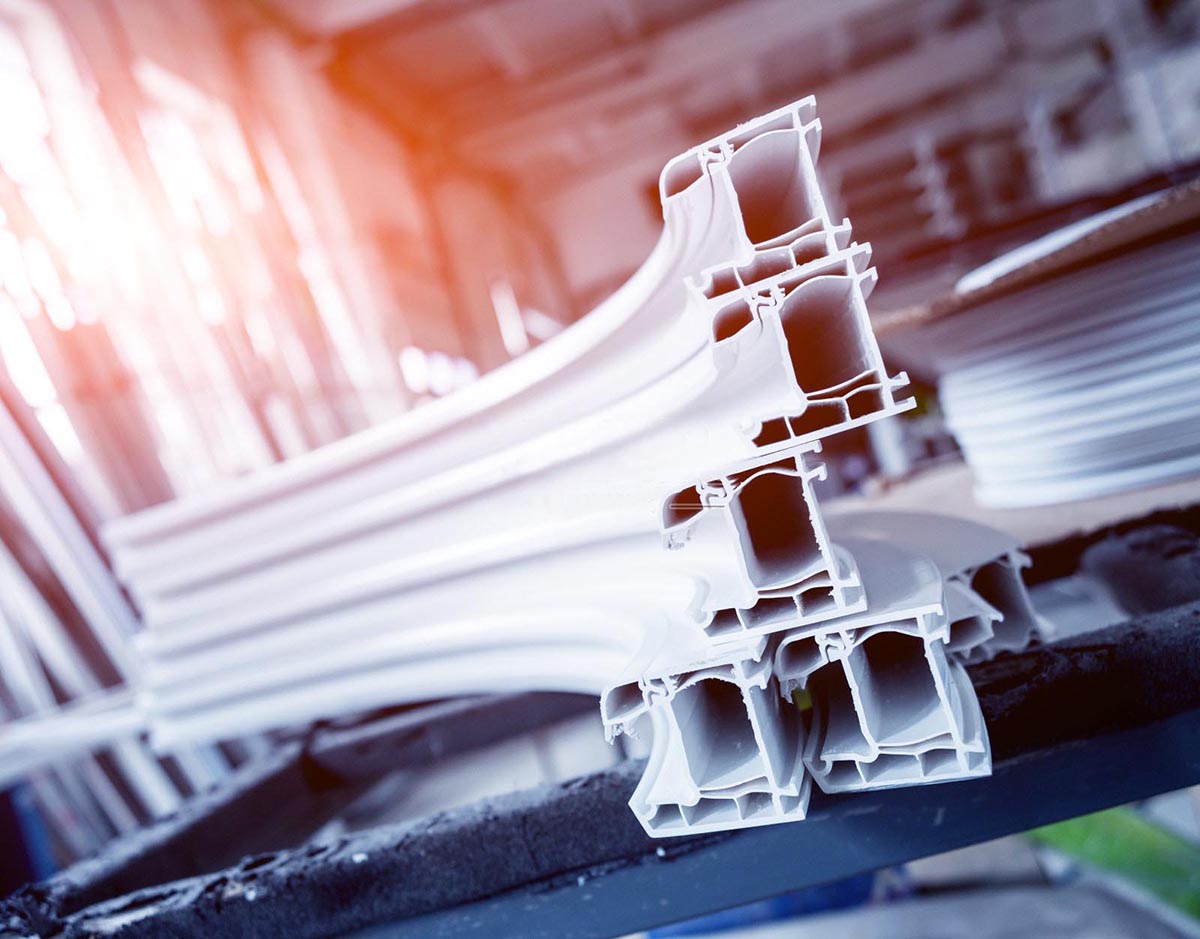

Polyvinyl Chloride (PVC) is a widely favored material in the construction industry, especially for window and door profiles. Its popularity is due to its durability, low maintenance requirements, and resistance to various environmental factors. However, raw PVC is susceptible to degradation when exposed to heat, ultraviolet (UV) light, and mechanical stress. To enhance its performance and longevity, PVC stabilizers are incorporated into the raw material during the manufacturing process. This article explores the application and benefits of PVC stabilizers in producing high-quality window and door profiles.

Functions of PVC Stabilizers in Window and Door Profiles

• Enhancing Thermal Stability: PVC stabilizers prevent PVC from decomposing under high temperatures during processing. This ensures the material retains its structure and properties throughout manufacturing and its end use.

• Providing UV Protection: Exposure to UV light can cause PVC to discolor and become brittle. PVC stabilizers protect the material from these effects, ensuring that window and door profiles maintain their appearance and functionality over time.

• Improving Mechanical Properties: PVC stabilizers strengthen PVC, enhancing its impact resistance and tensile strength. This is essential for window and door profiles, which must withstand mechanical stresses during installation and everyday use.

• Facilitating Processing: By improving the flow characteristics of PVC during extrusion, stabilizers contribute to more efficient manufacturing processes and consistent product quality.

Benefits of Using PVC Stabilizers

• Increased Durability: PVC stabilizers extend the life of PVC profiles by protecting them from thermal and UV degradation, ensuring long-lasting performance and appearance.

• Cost Efficiency: With enhanced durability, PVC profiles require less frequent replacement and maintenance, resulting in cost savings for manufacturers and consumers.

• Environmental Compliance: Using non-toxic PVC stabilizers like Ca-Zn and organotin compounds helps manufacturers adhere to environmental regulations and meet safety standards.

• Versatile Applications: Stabilized PVC profiles are suitable for a wide range of applications, from residential windows and doors to commercial construction projects.

In conclusion, PVC stabilizers are crucial in the production of durable and reliable window and door profiles. They provide the necessary thermal stability, UV protection, and mechanical strength to ensure the profiles meet the demanding requirements of the construction industry. Among all stabilizers, calcium-zinc PVC stabilizer stands out as a safe, non-toxic, and cost-effective option. This makes it a top choice for many profile manufacturers today.

Post time: Jun-18-2024