In the world of polymer processing, few additives work as quietly yet effectively as metal soap stabilizers. These versatile compounds are the backbone of PVC (polyvinyl chloride) stability, ensuring everything from rigid pipes to flexible films retains its integrity under heat, stress, and time. For manufacturers and engineers navigating the demands of modern PVC production, understanding their applications isn’t just technical—it’s critical to delivering durable, high-quality end products.

What Are Metal Soap Stabilizers?

Metal soap stabilizers are organometallic compounds formed by reacting fatty acids (like stearic or lauric acid) with metal oxides or hydroxides. Common metals include calcium, zinc, barium, cadmium (though increasingly phased out for environmental reasons), and magnesium. Their magic lies in balancing two key roles: stabilizing PVC during high-temperature processing (extrusion, injection molding) and protecting it from long-term degradation in end-use environments.

Why PVC Can‘t Thrive Without Them

PVC is a workhorse material, but it has an Achilles’ heel: thermal instability. When heated above 160°C (a standard temperature for processing), PVC’s polymer chains break down, releasing hydrochloric acid (HCl) in a self-accelerating reaction. This “dehydrochlorination” leads to discoloration, brittleness, and loss of mechanical strength—fatal flaws for critical applications like water pipes or medical tubing.

Metal soap stabilizers interrupt this cycle through three core mechanisms:

HCl Scavenging: They neutralize harmful HCl molecules, preventing them from catalyzing further degradation.

Ion Replacement: They replace unstable chlorine atoms in the polymer chain with more stable metal carboxylate groups, slowing breakdown.

Antioxidant Support: Many formulations work synergistically with antioxidants to quench free radicals, a byproduct of heat and UV exposure.

Key Applications in PVC Manufacturing

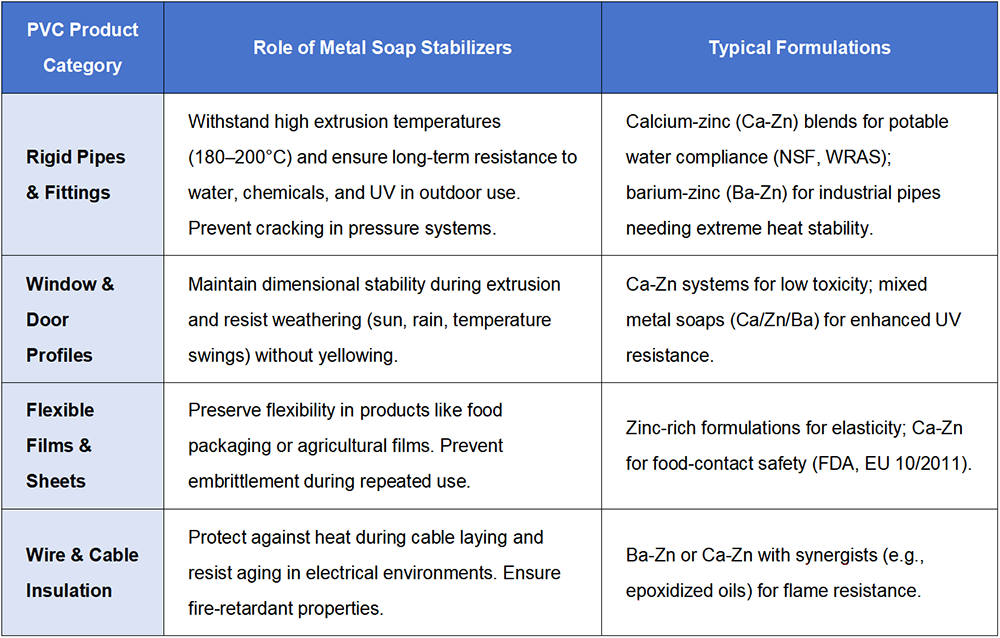

Metal soap stabilizers shine across a spectrum of PVC products, each demanding tailored performance:

Advantages That Drive Adoption

What makes metal soap stabilizers indispensable in PVC processing? Their unique blend of benefits:

Broad Compatibility: They work seamlessly with plasticizers, lubricants, and fillers (e.g., calcium carbonate), simplifying formulation.

Tailored Performance: By adjusting metal ratios (e.g., higher zinc for flexibility, more calcium for rigidity), manufacturers can fine-tune stability for specific needs.

Regulatory Compliance: Calcium-zinc systems meet strict global standards for food contact, potable water, and low toxicity—critical for consumer trust.

Cost-Effectiveness: They deliver robust stability at a lower cost compared to alternatives like organotins, making them ideal for high-volume production.

The Future: Sustainable and High-Performance

As the industry shifts toward sustainability, metal soap stabilizers are evolving too. Calcium-zinc formulations, in particular, are replacing traditional heavy-metal-based stabilizers (like lead or cadmium) to meet eco-friendly goals. Innovations in “green” metal soaps—using renewable fatty acids or biodegradable carriers—are further reducing their environmental footprint without sacrificing performance.

In short, metal soap stabilizers are more than additives—they’re enablers. They turn PVC’s potential into reliability, ensuring that the pipes, profiles, and films we depend on perform consistently, safely, and durably. For manufacturers aiming to stay ahead in a competitive market, choosing the right metal soap stabilizer isn’t just a technical decision—it’s a commitment to quality.

Ready to optimize your PVC formulations? Let’s connect to explore how tailored metal soap stabilizer solutions can elevate your products.

Post time: Jul-25-2025